Wide Area ATR Imaging Accessory

Introduction

The ATR accessory is used with an existing infra-red spectroscopic microscope called Spotlightwhich is made by Perkin Elmer. It is designed to be able to form spectrally-resolved images of "hard to analyse" samples such car tyres, pharpaceutical tablets, plastic films and surface deposits. In some cases these samples cannot be inspected by reflection or transmission spectroscopy, and in other cases it is simply much more conveneint and fast to use ATR imaging.

ATR stands for "Attenuated Total (internal) Reflection". Light (in this case infra-red) is passed into an optical material with a high refractive index (in this case germanium) and is directed internally towards a flat surface or interface. The sample of interest, which in general has a lower refractive index than the optical material (the index for germanium is about 4.0) is pressed against this interface. If the light is incident on the interface at an oblique angle which is near to or greater than the "critical angle", then it is totally reflected. This does not tell the whole story however: in fact, some energy escapes the surface and exists in the air or sample space on the other side. This energy does not propagate as a distinct light beam (it is called an "evanescent wave", but it is able to interact with any sample that is close enough to the interface. A sample may absorb some of the energy in a manner characteristic of the molecules of which it is composed. The reflection coefficient may be modified by the sample's refractive index also. By these mechanisms the "Total" internal reflection is "Attenuated" at certain wavelengths. One only has to attach a spectrometer and the reflections can be used to characterise the sample material. Because the evanescent wave only exists within a very narrow region just outside the high-index optic, the technique can be used to sample highly absorptive materials or very thin surface deposits.

The ATR imaging accessory provides the ability to collect many spectra from small but spatially distinct regions of a sample such as a chip of multi-layered car paint left at the scene of an accident or stuck to your car. Such "hyperspectral" images potentially permit very fine materials characterisation indeed: if the paint chip comes from your car you will be identified!

My responsibility in this project covered principally

- Optical design of the crystal (including detailed efficiency / optical throughput calculations)

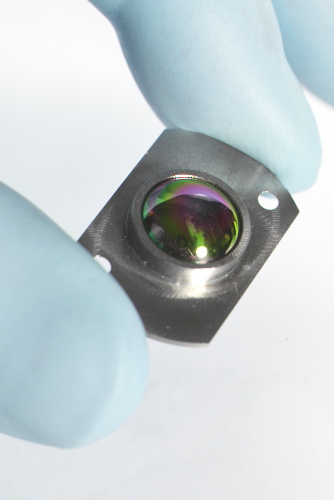

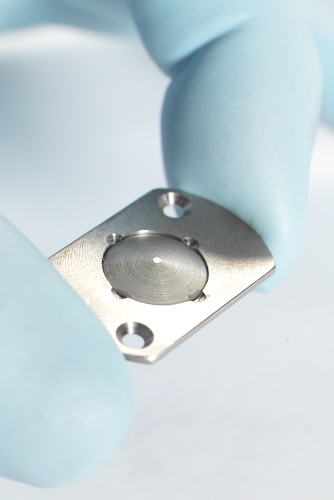

- Liaison with the manufacturer, design of novel alignment and bonding techniques and jigs for mounting the crystal into a customer-replaceable carrier.

- Originating a novel method for testing the spatial resolution of

the system using micro-embossed polymer structures.

- Defining test and acceptance procedures for the crystal, the

accessory and the Spotlight microscope system, including characterising

broad-band anti-reflection coatings.

- Collecting images and processing them (using principal components analysis amongst other techniques).

- Writing customer briefings and applications notes, and assising with sales.

Design and Construction

The accessory comprises two main parts: a germanium "ATR Crystal" which carries the infrared light and which is placed in contact with the sample and a mechanical arrangement that allows the sample to be positioned accurately and pressed gently but firmly against the crystal as well as interfacing with the existing microscope. Light from the Spotlight microscope enters and leaves the crystal via its curved surface (which is anti-reflection coated). The light is directed onto a small flat surface at the base of the crystal against which is pressed the sample of interest. I designed the crystal and a method for aligning and bonding it into its carrier: the assembly is user-replaceable in case of damage.

The accessory base provides a means for adjusting the sample position with respect to the crystal and of applying controlled pressure to the sample to bring it into intimate contact with the crystal.

Example Images - Car Paint Chip

Example Images - Structured Plastic Laminate

Light Control Film or "Privacy Film" (made by 3M) is a plastic sheet containing a micro-structure resembling a venetian blind. It is designed for use on ATM machines as a display filter: the "lovres" of the micro-scale venetian blind structure restrict the field of view so that only one person at a time can view the display. These images show processed cross-sections of the material mounted in resin: the internal structures are clearly visible, although the fact that the louvres are dyed black is not obvious!

Application Notes and Patents

I wrote two application notes on the accessory and its capabilities: Large-Area ATR Imaging

and Spatial

Resolution in ATR Imaging. Several patents were filed as a result

of the project, for example ATR Accessory

PatentThese application notes were written by Jerry Sellors, an experienced applications specialist. They show what the ATR Imaging Accessory can do for polymer laminates and pharmaceutical tablets.